SCHOOL PROJECT 2019

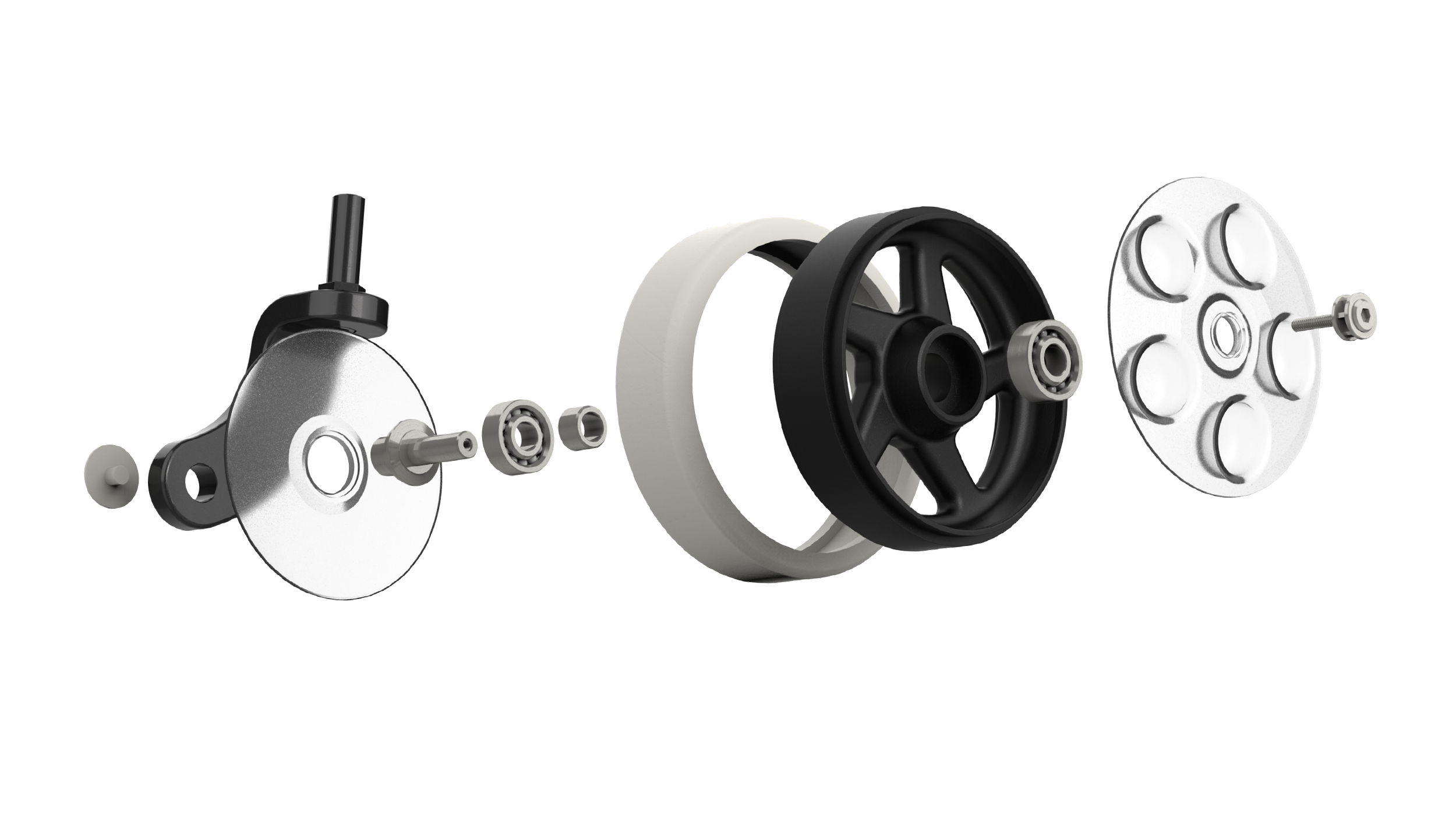

Wheelchair Caster

Hair and dust collecting in caster wheels is a common issue for wheelchair users. This often leads to issues requiring disassembly with tools and cleaning several times a week. This caster is designed to minimize hair collection by shielding the wheel hub and axle. The design allows for easy and accessible disassembly and reassembly by hand, saving the user the time and trouble to find the right tools.

Proposed production method:

Milled aluminum mono-fork design with injection-molded plastic disks on each side of the wheel to prevent hair from getting into the axle.

Weight-bearing axle milled from steel, friction-fitted into the fork.

Extruded steel spacer tube to transfer clamping force through the bearings, ensuring they remain aligned.

Asymmetrical wheel made from injection-molded plastic with a rubber tire molded onto it.

Design process

The project was kicked off with a visit to a wheelchair user who demonstrated the caster-related issues they face daily. The main issues were hair accumulating around the axle, jamming the wheel several times a week, and the constant need to carry tools for disassembly and cleaning.

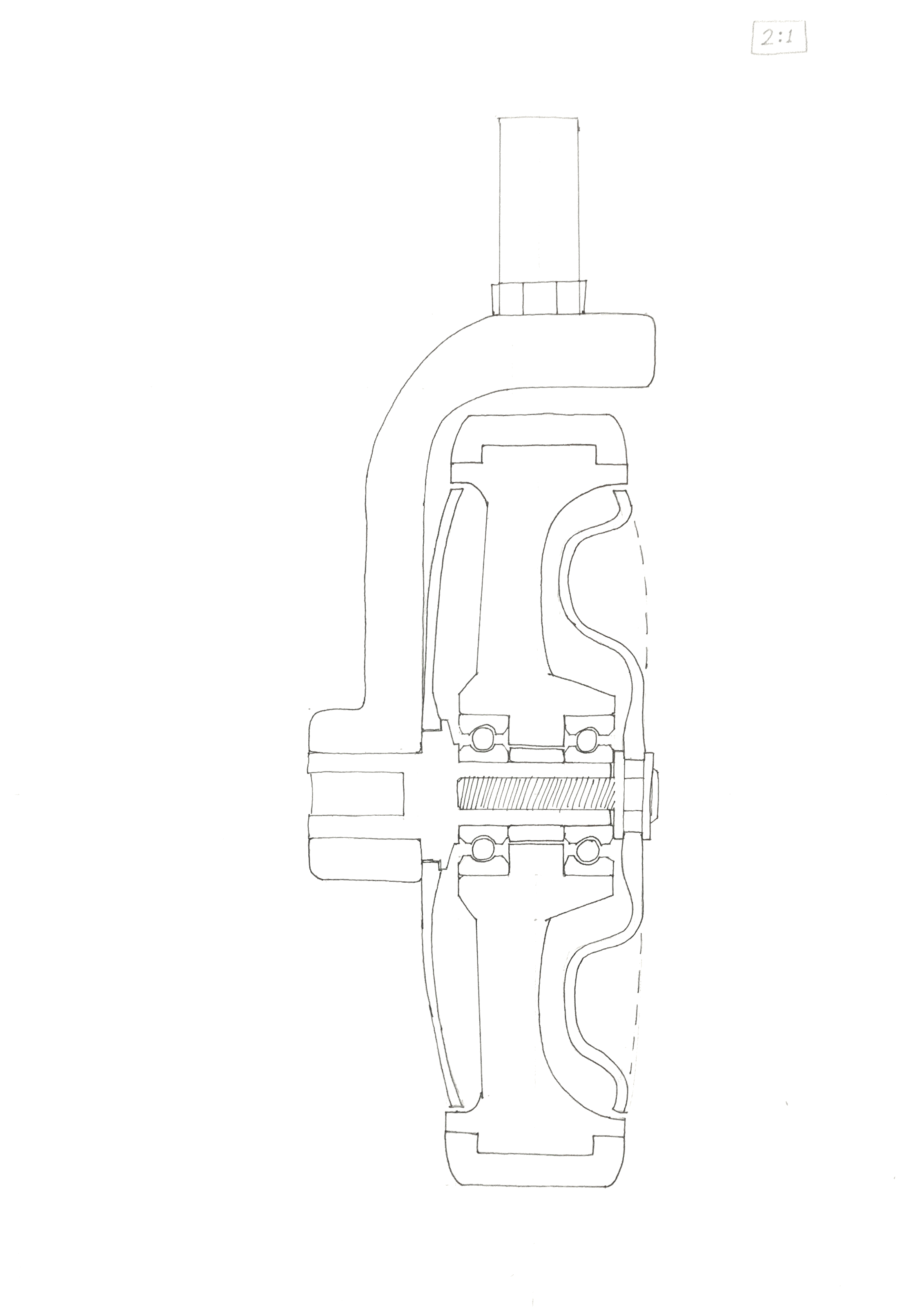

After extensive sketching, a prototype was designed, 3D-modelled and 3D-printed. Basic prototype testing was done by rolling the caster on the floor by hand, comparing the amount of hair collected to that of a standard wheelchair caster. The time required for assembly and disassembly was also compared, confirming that the tool-less design was significantly faster and easier to deal with.

Modelled in SolidWorks

3D-printed prototype

Further improvements

With more time, I would have liked to continue the project by conducting more realistic testing with a sturdier prototype and making further improvements to the design. For example, a suspected weak point is the screw-on disk which could loosen due to vibrations or bumping into obstacles. This could be improved with a locking mechanism, or replacing the screw with a ball lock pin.